What is Fluid Power?

Fluid power (hydraulic and pneumatic) technology is used to generate, control and transmit power in a variety of applications that you see every day. You can find fluid power components in aerospace, agriculture, automation, construction, energy, entertainment, forestry, food processing, lawn & garden, marine, material handling, medical devices, mining, oil & gas, packaging, transportation and more.

Off-highway equipment is probably the most common application of hydraulics. Whether it’s construction, mining, agriculture, waste reduction or utility equipment, hydraulics provides the power and control to tackle the task at hand. Hydraulics is also widely used in heavy industrial equipment in factories, in marine and offshore equipment for lifting, bending, pressing, cutting, forming, and moving heavy work pieces.

Factory automation is the largest sector for pneumatics technology, which is widely used for manipulating products in manufacturing, processing and packaging operations. Pneumatics is also widely used in medical and food processing equipment as well as in chemical plants and refineries to actuate large valves. It’s used on mobile equipment for transmitting power where hydraulics or electromechanical drives are less practical or not as convenient and in on-highway trucking for various vehicle functions. And of course, vacuum is used for lifting and moving work pieces and products. In fact, combining multiple vacuum cups into a single assembly allows lifting large and heavy objects.

Fluid Power Moves the World

Fluid power is a term describing hydraulics and pneumatics technologies. Both technologies use a fluid (liquid or gas) to transmit power from one location to another. With hydraulics, the fluid is a liquid (usually oil), whereas pneumatics uses a gas (usually compressed air).

Both are forms of power transmission, which is the technology of converting power to a more useable form and distributing it to where it is needed. The common methods of power transmission are electrical, mechanical, and fluid power.

Although they sometimes are viewed as competing technologies, no single method of power transmission is the best choice for all applications. In fact, most applications are served by a combination of technologies. However, fluid power offers important advantages over the other technologies.

FLUID POWER SYSTEMS:

- Easily produce linear motion using hydraulic or pneumatic cylinders, whereas electrical and mechanical methods usually must use a mechanical device to convert rotational motion to linear.

- Generally, can transmit equivalent power within a much smaller space than mechanical or electrical drives can, especially when extremely high force, or torque, is required.

- Offer simple and effective control of direction, speed, force, and torque using simple control valves. Fluid power systems often do not require electrical power, which eliminates the risk of electrical shock, sparks, fire, and explosions.

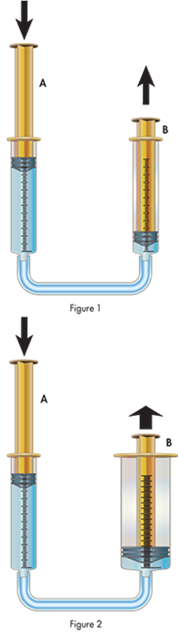

To visualize a basic hydraulic system, think of two syringes connected together with tubing and filled with water (see Figure 1). Syringe A represents a pump, and Syringe B represents an actuator, in this case a cylinder. Pushing the plunger of Syringe A pressurizes the liquid inside.

This fluid pressure acts equally in all directions (Pascal’s Law) and causes the water to flow into the tube and into Syringe B. If you placed a 5 lb. object on top of the plunger of Syringe B, you would need to push on Syringe A’s plunger with at least 5 lbs. of force to move the weight upward. If the object weighed 10 lbs., you would have to push with at least 10 lbs. of force to move it upward.

If the area of the plunger of Syringe A is 1 sq. in. and you push with 5 lbs. of force, the fluid pressure will be 5 psi. Because fluid pressure acts equally in all directions, if the object on Syringe B (with an area of 1 sq. in.) weighs 10 lbs., fluid pressure would have to exceed 10 psi to move it. If the diameter of Syringe B is doubled (see Figure 2), the area of the plunger becomes four times larger. This means a 10 lb. weight would be supported on 4 sq. in. of fluid.

Therefore, fluid pressure would only have to exceed 2.5 psi (10 lbs. ÷ 4 sq. in.) to move the object upward. Moving the 10 lb. object would only require 2.5 lbs. of force on the plunger of Syringe A, but the plunger on Syringe B would move upward only ¼ as far as when both plungers were the same size. This is the essence of fluid power: varying the sizes of pistons and cylinders allows multiplying the applied force.

In actual hydraulic systems, pumps contain many pistons or other types of pumping chambers. They are driven by a prime mover (usually an electric motor, diesel engine, or gas engine) that rotates at several hundred revolutions per minute (rpm). Each rotation causes the pump’s pistons to extend and retract, drawing fluid in and pushing it out to the hydraulic circuit.

Hydraulic systems typically operate at fluid pressures of thousands of psi. A system that can develop 2,000 psi can push with 10,000 lbs. of force from a cylinder about the size of a soda can.

The principles of pneumatics are the same as those for hydraulics, but pneumatics transmits power using a gas instead of a liquid. Compressed air is usually used, but nitrogen or other inert gases can be used for special applications. With pneumatics, air is usually pumped into a receiver using a compressor.

The receiver holds a large volume of compressed air to be used by the pneumatic system as needed. Atmospheric air contains dirt, water vapor, and other contaminants, so filters and air dryers are often used to keep compressed air clean and dry, improving the reliability and service life of the components and system. Pneumatic systems also use valves for controlling direction, pressure, and speed of actuators.

used to keep compressed air clean and dry, improving the reliability and service life of the components and system. Pneumatic systems also use valves for controlling direction, pressure, and speed of actuators.

Most pneumatic systems operate at pressures of about 100 psi or less. Because of the lower pressure, cylinders and other actuators must be sized larger than their hydraulic counterparts to apply an equivalent force. For example, a hydraulic cylinder with a 2 in. diameter piston (3.14 sq. in. area) and fluid pressure of 1,000 psi can push with 3140 lbs. of force. A pneumatic cylinder using 100 psi air would need a bore of almost 6½ in. (33 sq. in.) to develop the same force.

Even though pneumatic systems usually operate at much lower pressure than hydraulic systems do, pneumatics holds many advantages that make it more suitable for many applications. Because pneumatic pressures are lower, components can be made of thinner and lighter weight materials, such as aluminum and engineered plastics. Hydraulic components are generally made of steel and ductile or cast iron.

Hydraulic systems are often considered rigid, whereas pneumatic systems usually offer some cushioning, or “give.” Pneumatic systems are generally simpler because air can be exhausted to the atmosphere, whereas hydraulic fluid usually is routed back to a fluid reservoir.

Pneumatics also holds advantages over electromechanical power transmission methods. Electric motors are often limited by heat generation. Heat generation is usually not a concern with pneumatic motors because the stream of compressed air running through them carries heat from them. Because pneumatic components require no electricity, they don’t need the bulky, heavy, and expensive explosion-proof enclosures required by electric motors.

Even without special enclosures, electric motors are substantially larger and heavier than pneumatic motors of equivalent power rating. If overloaded, pneumatic motors will stall and not use any power. Electric motors can overheat and burn out if overloaded. Torque, force, and speed control with pneumatics often requires simple pressure- or flow-control valves, as opposed to more expensive and complex electrical drive controls. As with hydraulics, pneumatic actuators can instantly reverse direction, whereas electromechanical components often rotate with high momentum, which can delay changes in direction.

Another advantage of pneumatics is its ability to use vacuum for picking up and moving objects. Vacuum can be thought of as negative pressure — by removing air (evacuating) from the volume between two parts, atmospheric pressure outside the volume pushes the parts together. For example, attempting to pick up a single sheet of paper or a raw egg presents a challenge with conventional grippers. But with a vacuum pneumatic system, evacuating a suction cup in contact with a sheet of paper or eggshell causes atmospheric pressure to push the object against the cup, allowing it to be lifted.

Standard electric motors typically rotate at 1,800 or 3,600 rpm — much faster than is practical for most machines. Gasoline and diesel engines also rotate at thousands of rpm when powering equipment. Therefore, some form of power transmission is needed to convert this power to a more useable form — slower speed and, often, linear motion instead of rotary.

Mechanical power transmission methods include gears, chains, and belts that reduce speed and increase torque (twisting force). Components like ball screws, rack-and-pinion assemblies, and chain drives convert rotational motion and torque to linear motion and force.

Electrical methods of power transmission regulate electrical power to control speed and torque. However, they cannot convert rotary motion to linear motion directly. When linear output is needed, a linear motor may be used, but its high cost often makes mechanical devices more practical for producing linear motion and force.

In many cases, mechanical and electrical methods cannot provide a practical power transmission solution. In these instances, fluid power — whether hydraulic or pneumatic — is used because it can deliver linear and rotary motion with high force and torque in a compact package.

A cement mixer is an example of how different methods of power transmission can be used. Early cement mixers relied on mechanical drives powered by the truck’s engine or transmission. A system of gears, chain drives, and drive shafts provided the necessary speed and torque but was complex and maintenance-intensive. Speed control was difficult, as the drum's rotation depended on the engine or transmission speed, often causing it to rotate at suboptimal speeds.

An electrical drive could offer better speed control but would require a large motor, gearbox, and generator, making the solution heavy and bulky. These constraints led to the adoption of hydraulic drives.

Hydraulic drives use a pump, hydraulic motor, and valves to precisely control drum speed, independent of engine speed. The components are compact: the pump fits within the truck framework, and the hydraulic motor is significantly smaller than an equivalent electric motor-gearbox combination. Hydraulic systems allow for manual speed control and optimal drum rotation with less complexity.

Did you know that fluid power systems transmit more power in a smaller space than other forms of power transmission? This means it is the technology of choice for dozens of industries and thousands of applications.

Get an economic snapshot of the industry, NFPA workforce development programs, career opportunities, and more in the video below.

Learn more about fluid power technology and applications, get career inspiration from others in the fluid power industry, and more.

You'll find the latest innovations in fluid power on the podcast, with new episodes twice a month. Learn about the industry's efforts to improve sustainability and efficiency, while redusing noise.

Like content like this, and you are interested in starting your fluid power career? Consider joining our network for resources to help you learn about the fluid power industry.

Fluid power is a workhorse of the U.S. economy—a cross-cutting technology of choice for dozens of industries and hundreds of applications. That’s one of the many conclusions in the new report, the Fluid Power Industry Fact Sheet, published by the National Fluid Power Association.

Learn more about the industry's size and scope, economic impact, and where it's headed in this updated fact sheet. Click the link below to download the report.